Enhance Efficiency

페이지 정보

작성자 Balancingpuh 작성일 24-11-13 04:26 조회 4 댓글 0본문

balancing stands

balancing stands

Balancing Stands: Your Comprehensive Guide

Balancing stands play a crucial role in the world of machinery and engineering, primarily focusing on the dynamic balancing of various rotating components. These simple yet effective devices are high in demand for providing quality balancing services at minimal costs. The stands are often designed using a flat plate or frame mounted on cylindrical compression springs, allowing them to accommodate a wide variety of rotors, including those found in crushers, fans, turbines, and many other machinery types.

One of the fundamental principles behind these balancing stands is ensuring that the frequency of the natural vibrations of the plate, which supports the rotor being balanced, is significantly lower than the operational frequency of the rotor itself. Typically, this frequency ratio is maintained at two to three times lower during the balancing process, thereby optimizing the stand's performance.

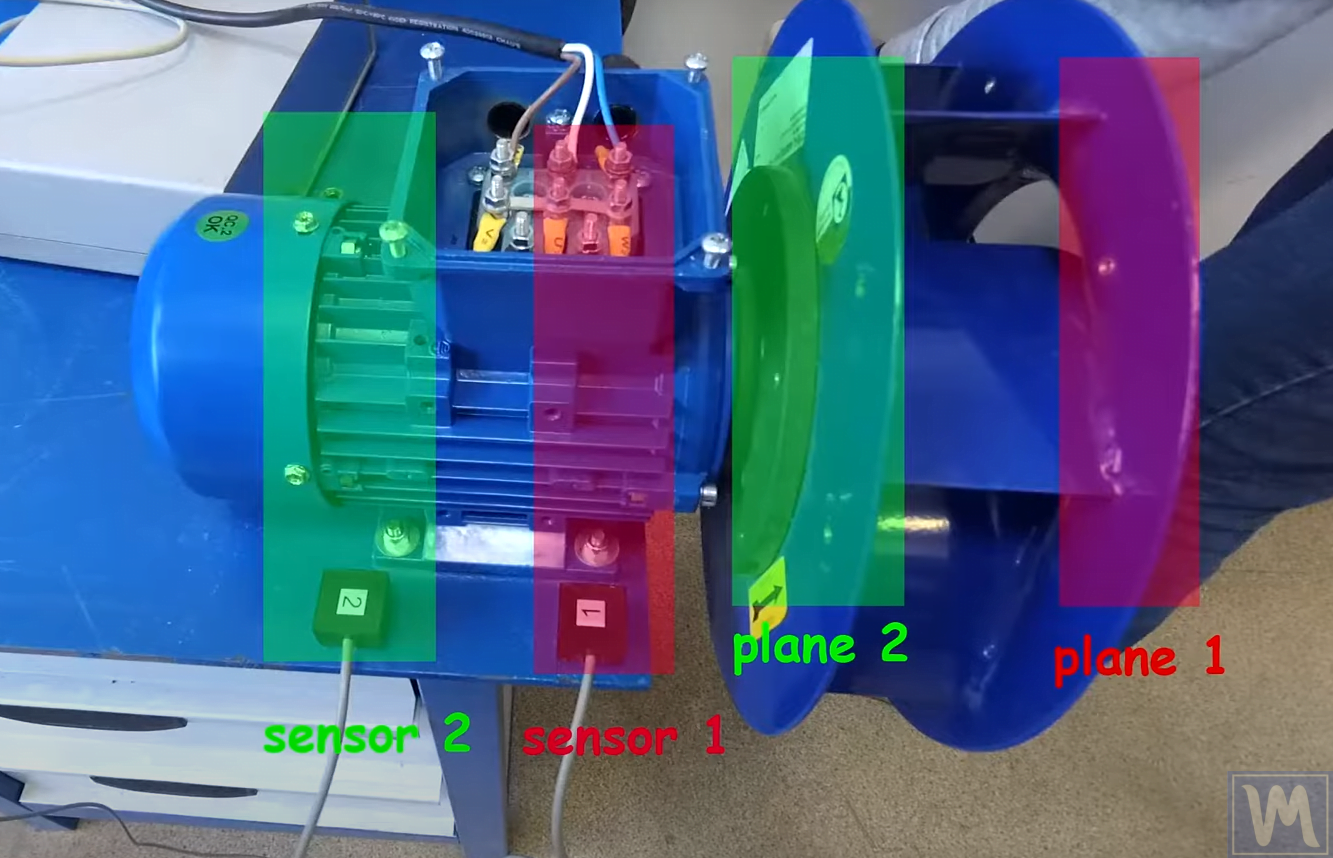

For instance, consider a balancing stand designed for abrasive wheels. The stand comprises a plate mounted on four cylindrical springs, in conjunction with an electric motor whose rotor also serves as a spindle. This spindle is fitted with a mandrel that secures the abrasive wheel for balancing. A significant feature of this setup is the inclusion of an impulse sensor, which monitors the angle of the motor rotor's rotation. This sensor becomes an essential part of the measuring system of "Balanset," aiding in the precise determination of where corrective mass needs to be removed from the abrasive wheel to achieve balance.

Another diverse application of balancing stands is in vacuum pump maintenance. Stands designated for this purpose operate in a similar manner, utilizing a plate and cylindrical springs to secure the vacuum pump, which can reach impressive speeds of up to 60,000 RPM. Here, the inclusion of vibration sensors is vital as they measure vibrations at various height sections of the pump. Additionally, the laser phase angle sensor helps synchronize vibration measurements with the rotor's rotational angle. This setup, although appearing simplistic, achieves high standards of balancing, meeting the tolerance for class G0.16 as defined by ISO 1940-1-2007. During balancing at subcritical speeds, residual vibration levels can be maintained below 0.01 mm/sec.

Moreover, balancing stands have proven their effectiveness in balancing fan rotors. Many manufacturers have turned to these stands for their fan production lines. Detailed results have showcased substantial improvements in residual vibration levels during fan balancing operations. For instance, one stand displayed residual vibration levels of just 0.8 mm/s, significantly surpassing the tolerance limits established for Category BV5 fans as per ISO 31350-2007 standards, which govern vibration metrics for industrial fans.

Furthermore, there are various designs tailored specifically for balancing different types of fans. Stands constructed according to meticulous recommendations have reported stellar performances, with some setups ensuring residual vibration levels below 0.1 mm/s during fan balancing. Such results underscore the remarkable precision and quality achievable through well-designed balancing stands.

In practice, the widespread use of balancing stands extends beyond just balancing operations. They serve as indispensable aids in machinery maintenance, ensuring optimal performance and extending the operational lifespan of components by minimizing vibrations and imbalances that could lead to wear and tear. Users can rely on balancing stands to not only improve the efficiency of rotors but also to enhance the overall safety and reliability of machines.

For those interested in acquiring balancing stands, a variety of options are available in the market. Portable balancers and vibration analyzers, such as the "Balanset" series, include models designed to cater to specific needs. Equipment like electric motors with spindle capabilities, reflective tape, magnetic stands, optical sensors, and vibration sensors are widely accessible. This diverse lineup ensures that users can find the exact tools necessary for their balancing tasks, accommodating the array of rotor types and sizes they may encounter.

The importance of balancing stands cannot be overstated. Companies dealing in manufacturing, maintenance, and repair of rotating machinery must invest in quality balancing solutions to uphold standards and meet industry regulations. The integration of modern technologies such as laser sensors and advanced measuring systems enhances both the accuracy and efficiency of these stands.

Through careful design and engineering, balancing stands not only facilitate the balancing of various rotors but also support industries in achieving their operational goals. The choice of a suitable stand often determines the effectiveness of maintenance procedures and the longevity of machinery components. A detailed understanding of balancing stands, including their operational principles and the technology behind them, empowers businesses to optimize their processes and uphold high-quality production standards.

In summary, balancing stands represent a vital tool in the engineering toolbox, essential for ensuring that rotors operate smoothly and efficiently. By incorporating a range of advanced technologies and principles, these stands deliver exceptional performance, making them indispensable for any operation involving rotating machinery. Investing in quality balancing stands ultimately contributes to enhanced operational efficiency, reduced downtime, and superior product performance for various industries.

관련링크

- https://vibromera.eu/ 1회 연결

- https://vibromera.eu/ 1회 연결

댓글목록 0

등록된 댓글이 없습니다.